Polyvinyl Chloride (PVC) waterproof materials have become indispensable across various industries due to their versatility, durability, and cost-effectiveness. From early uses in protective coverings to today’s specialized applications, PVC materials have evolved significantly. This article delves into the development of PVC waterproof materials, common specifications, and their wide-ranging applications.

The journey of PVC began in the 1920s as a byproduct of vinyl chloride research. It wasn’t until the 1930s that PVC found commercial viability, leading to its widespread adoption. The material’s resistance to water, chemicals, and UV rays made it an ideal choice for waterproofing solutions.

In the 1950s, the introduction of PVC tarpaulin marked a turning point, providing a durable and flexible waterproofing solution. Over time, innovations such as PVC-coated fabrics, which combine the strength of base fabrics with the protective qualities of PVC, have further expanded the material’s applications.

Industry-standard specifications for PVC waterproof materials include:

-

PVC Coated Polyester Fabric (250D, 500D, 1000D): This material is widely used in applications requiring high durability and flexibility, such as truck covers and banners. The 500D and 1000D denote the denier count of the polyester fabric, which affects the material’s strength and weight.

Fire Resistant Tent Tarps Heavy Duty PVC Coated Covers Tarpaulin PVC Fabric for Tent

-

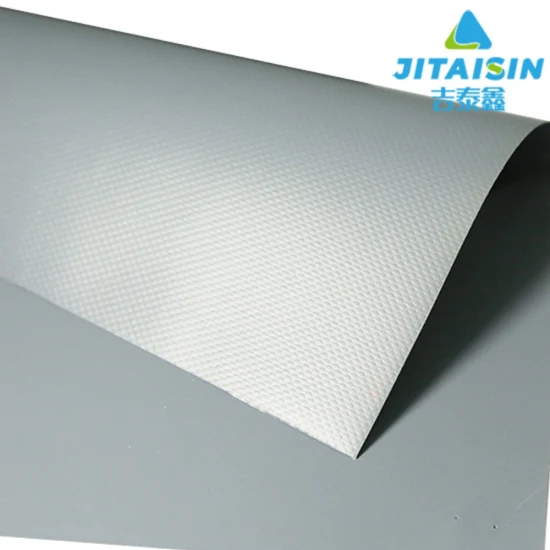

PVC Laminated Polyester Fabric (500D, 840D, 1000D): This variant offers a smoother finish and is typically used in high-visibility applications like billboards and tents. It provides excellent printability and weather resistance.

High Quality Polyester Laminated Plain PVC Length Tarpaulin Tarps Roll

High Quality Polyester Laminated Plain PVC Length Tarpaulin Tarps Roll

-

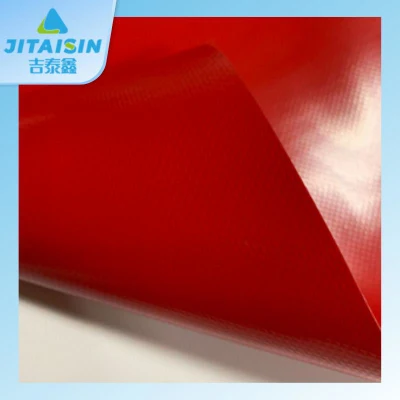

PVC Coated Tarpaulin (600g/m² to 900g/m²): This heavy-duty material is designed for use in demanding environments, such as industrial covers and outdoor storage. The weight per square meter indicates the thickness and robustness of the tarpaulin.

Canopy PVC Coated Tarpaulin, Canvas Carport Covers Canvas Tarpaulin for Truck Cover

-

PVC Film (0.12mm to 0.50mm thickness): Used for inflatables and waterproof membranes, this material is known for its flexibility and airtightness. The thickness varies depending on the application, with thicker films offering greater durability.

Waterproof Colorful PVC Film for Raincoat

The versatility of PVC waterproof materials has led to their adoption across multiple industries. Key applications include:

-

Waterproof Bags: PVC-coated polyester fabrics, especially in 500D and 1000D, are ideal for making waterproof bags. These fabrics offer the right balance of strength and water resistance, making them suitable for outdoor gear and protective covers.

-

Truck Covers: Heavy-duty PVC-coated tarpaulin (600g/m² to 900g/m²) is a preferred choice for truck covers, providing excellent protection against rain, wind, and UV exposure. This material’s durability ensures that cargo remains safe during transportation.

-

Outdoor Advertising: PVC-laminated polyester fabric (500D, 1000D) is commonly used for banners and billboards due to its smooth finish and high resistance to weathering. It allows for vibrant printing, making it ideal for outdoor advertising.

-

Inflatable Products: The PVC film used in inflatables typically ranges from 0.12mm to 0.50mm in thickness, depending on the product requirements. This material is crucial in manufacturing bounce houses, inflatable boats, and air mattresses, where both flexibility and durability are essential.

-

Construction and Agriculture: PVC-coated tarpaulins are frequently used on construction sites for temporary shelters and in agriculture for crop protection. Their ability to withstand harsh environmental conditions makes them invaluable in these sectors.

-

Automotive Industry: In the automotive sector, PVC-coated tarpaulin is used for car covers, seat covers, and protective linings, offering excellent waterproofing and durability. This material ensures vehicles and equipment are well-protected from the elements.

The development of PVC waterproof materials has had a profound impact on various industries. From its early days to the creation of specialized materials like PVC-coated polyester fabric and PVC-laminated polyester fabric, PVC continues to provide reliable, durable, and versatile waterproofing solutions. With applications ranging from waterproof bags to PVC tarpaulin truck covers and PVC film for inflatables, PVC remains a cornerstone in modern industrial and commercial waterproofing.