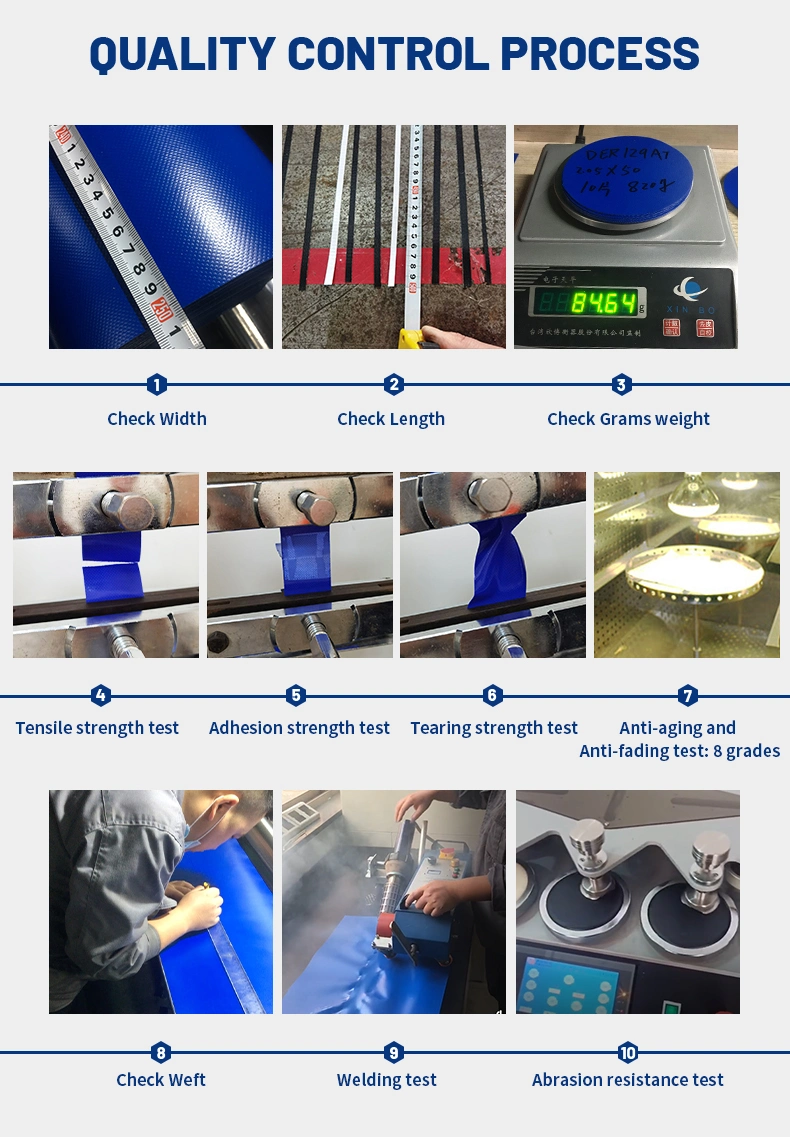

At our company, we understand the importance of producing high-quality PVC tarpaulin that meets the diverse needs of our clients. To ensure that our products are durable, reliable, and suitable for a wide range of applications, we follow a comprehensive quality control process. This process involves several rigorous tests and measurements to guarantee the best performance. Below, we outline the 10 key steps we take to ensure the quality of every PVC tarpaulin product.

1. Check Width

The first step in our process is to measure the width of the PVC tarpaulin to ensure that it meets the required specifications. Accurate width is essential for various applications, such as truck covers and industrial uses.

2. Check Length

Next, we measure the length of the material. Precise length measurement is crucial for projects where the PVC tarpaulin must cover large surfaces, ensuring that no adjustments or additional materials are needed during installation.

3. Check Grams Weight

Weight consistency is a critical factor for PVC tarpaulin durability. By checking the grams per square meter (GSM), we confirm that the material has the correct density and strength to withstand harsh environmental conditions.

4. Tensile Strength Test

Tensile strength refers to the PVC tarpaulin’s ability to resist breaking under tension. This test ensures that the material can endure stretching forces without tearing, which is essential for its use in demanding conditions like transportation covers and outdoor shelters.

5. Adhesion Strength Test

The bond between the PVC coating and the fabric is tested to verify adhesion strength. Strong adhesion prevents the material from peeling or separating, ensuring long-term durability, especially in PVC coated tarpaulin products.

6. Tearing Strength Test

Tear resistance is a vital quality for PVC tarpaulin, as it determines how well the material can withstand punctures or cuts without ripping further. This test ensures the tarpaulin can handle rugged conditions, making it ideal for applications such as heavy-duty truck and boat covers.

7. Anti-aging and Anti-fading Test (8 Grades)

To ensure long-lasting performance, we conduct anti-aging and anti-fading tests. Our PVC tarpaulin undergoes exposure to UV light and other environmental stressors to ensure it remains functional and visually intact for extended periods. The material is graded on an 8-point scale, with 8 being the highest.

8. Check Weft

Checking the weft, or the crosswise threads, is crucial to ensure the fabric’s overall structure is balanced. This test ensures the PVC tarpaulin maintains its integrity during use, preventing deformations or weak spots that could compromise its durability.

9. Welding Test

For certain applications, PVC tarpaulin needs to be welded to create larger or custom shapes. Our welding test ensures that the material fuses properly, without weak points, providing a strong, seamless bond that enhances waterproofing and strength.

10. Abrasion Resistance Test

Finally, we perform an abrasion resistance test to assess how well the PVC tarpaulin can withstand friction and wear. This test is critical for applications where the material may be exposed to rough surfaces or continuous movement, ensuring it remains intact over time.

Conclusion

By following this meticulous quality control process, we guarantee that our PVC tarpaulin products meet the highest standards of durability, performance, and longevity. Whether you need PVC laminated tarpaulin for covers or PVC coated tarpaulin for more heavy-duty applications, our products are tested to withstand the most challenging environments.